All Categories

View All >-

Limiting Speed TIMKEN 220TP175 Thrust cylindrical roller bearingsSee More>

Limiting Speed TIMKEN 220TP175 Thrust cylindrical roller bearingsSee More> -

Weight TIMKEN A-5240-WM A5200 Metric Cylindrical Roller Radial BearingSee More>

Weight TIMKEN A-5240-WM A5200 Metric Cylindrical Roller Radial BearingSee More> -

60 mm x 130 mm x 46 mm da max NTN NJ2312ET2C4 Single row Cylindrical roller bearingSee More>

60 mm x 130 mm x 46 mm da max NTN NJ2312ET2C4 Single row Cylindrical roller bearingSee More> -

Chamfer rsmin TIMKEN NNU4964MAW33 Two-Row Cylindrical Roller Radial BearingsSee More>

Chamfer rsmin TIMKEN NNU4964MAW33 Two-Row Cylindrical Roller Radial BearingsSee More>

Featured Products

Our Manufacturer with main products: Thrust cylindrical roller bearings, A5200 Metric Cylindrical Roller Radial Bearing, Single row Cylindrical roller bearing

-

Chamfer rsmin TIMKEN NNU4964MAW33 Two-Row Cylindrical Roller Radial Bearings

Chamfer rsmin TIMKEN NNU4964MAW33 Two-Row Cylindrical Roller Radial Bearings

-

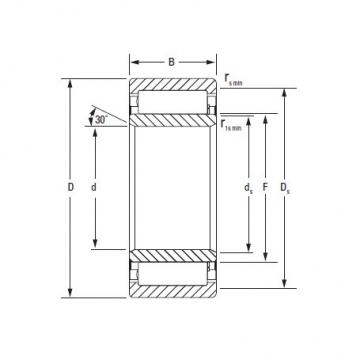

Width B TIMKEN NNU4934MAW33 Two-Row Cylindrical Roller Radial Bearings

Width B TIMKEN NNU4934MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Lubrication Hole Diameter h TIMKEN NNU4160MAW33 Two-Row Cylindrical Roller Radial Bearings

Lubrication Hole Diameter h TIMKEN NNU4160MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Chamfer rsmin TIMKEN NNU49/530MAW33 Two-Row Cylindrical Roller Radial Bearings

Chamfer rsmin TIMKEN NNU49/530MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Backing Shaft Diameter ds TIMKEN NNU40/500MAW33 Two-Row Cylindrical Roller Radial Bearings

Backing Shaft Diameter ds TIMKEN NNU40/500MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Static Load Rating Co TIMKEN NNU49/600MAW33 Two-Row Cylindrical Roller Radial Bearings

Static Load Rating Co TIMKEN NNU49/600MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Backing Shaft Diameter ds TIMKEN NNU4932MAW33 Two-Row Cylindrical Roller Radial Bearings

Backing Shaft Diameter ds TIMKEN NNU4932MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Lubrication Groove g TIMKEN NNU40/530MAW33 Two-Row Cylindrical Roller Radial Bearings

Lubrication Groove g TIMKEN NNU40/530MAW33 Two-Row Cylindrical Roller Radial Bearings

-

DUR/DOR F/E TIMKEN NNU4948MAW33 Two-Row Cylindrical Roller Radial Bearings

DUR/DOR F/E TIMKEN NNU4948MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Width B TIMKEN NNU4188MAW33 Two-Row Cylindrical Roller Radial Bearings

Width B TIMKEN NNU4188MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Backing Housing Diameter Ds TIMKEN NNU4196MAW33 Two-Row Cylindrical Roller Radial Bearings

Backing Housing Diameter Ds TIMKEN NNU4196MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Thermal Speed Ratings - Grease TIMKEN NNU4992MAW33 Two-Row Cylindrical Roller Radial Bearings

Thermal Speed Ratings - Grease TIMKEN NNU4992MAW33 Two-Row Cylindrical Roller Radial Bearings

-

DUR/DOR F/E TIMKEN NNU4980MAW33 Two-Row Cylindrical Roller Radial Bearings

DUR/DOR F/E TIMKEN NNU4980MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Chamfer rsmin TIMKEN NNU4968MAW33 Two-Row Cylindrical Roller Radial Bearings

Chamfer rsmin TIMKEN NNU4968MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Chamfer r1smin3 TIMKEN NNU4076MAW33 Two-Row Cylindrical Roller Radial Bearings

Chamfer r1smin3 TIMKEN NNU4076MAW33 Two-Row Cylindrical Roller Radial Bearings

-

DUR/DOR F/E TIMKEN NNU4996MAW33 Two-Row Cylindrical Roller Radial Bearings

DUR/DOR F/E TIMKEN NNU4996MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Chamfer rsmin TIMKEN NNU4930MAW33 Two-Row Cylindrical Roller Radial Bearings

Chamfer rsmin TIMKEN NNU4930MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Backing Shaft Diameter ds TIMKEN NNU4956MAW33 Two-Row Cylindrical Roller Radial Bearings

Backing Shaft Diameter ds TIMKEN NNU4956MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Dimension S4 TIMKEN NNU4944MAW33 Two-Row Cylindrical Roller Radial Bearings

Dimension S4 TIMKEN NNU4944MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Lubrication Groove g TIMKEN NNU4072MAW33 Two-Row Cylindrical Roller Radial Bearings

Lubrication Groove g TIMKEN NNU4072MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Chamfer r1smin3 TIMKEN NNU4092MAW33 Two-Row Cylindrical Roller Radial Bearings

Chamfer r1smin3 TIMKEN NNU4092MAW33 Two-Row Cylindrical Roller Radial Bearings

-

DUR/DOR F/E TIMKEN NNU49/750MAW33 Two-Row Cylindrical Roller Radial Bearings

DUR/DOR F/E TIMKEN NNU49/750MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Weight TIMKEN NNU49/800MAW33 Two-Row Cylindrical Roller Radial Bearings

Weight TIMKEN NNU49/800MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Thermal Speed Ratings - Grease TIMKEN NNU49/630MAW33 Two-Row Cylindrical Roller Radial Bearings

Thermal Speed Ratings - Grease TIMKEN NNU49/630MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Bore d TIMKEN NNU4148MAW33 Two-Row Cylindrical Roller Radial Bearings

Bore d TIMKEN NNU4148MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Chamfer rsmin TIMKEN NNU4084MAW33 Two-Row Cylindrical Roller Radial Bearings

Chamfer rsmin TIMKEN NNU4084MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Weight TIMKEN NNU49/900MAW33 Two-Row Cylindrical Roller Radial Bearings

Weight TIMKEN NNU49/900MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Chamfer r1smin3 TIMKEN NNU4192MAW33 Two-Row Cylindrical Roller Radial Bearings

Chamfer r1smin3 TIMKEN NNU4192MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Lubrication Hole Diameter h TIMKEN NNU4168MAW33 Two-Row Cylindrical Roller Radial Bearings

Lubrication Hole Diameter h TIMKEN NNU4168MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Lubrication Groove g TIMKEN NNU49/710MAW33 Two-Row Cylindrical Roller Radial Bearings

Lubrication Groove g TIMKEN NNU49/710MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Backing Shaft Diameter ds TIMKEN NNU4156MAW33 Two-Row Cylindrical Roller Radial Bearings

Backing Shaft Diameter ds TIMKEN NNU4156MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Dynamic Load Rating C11 TIMKEN NNU4988MAW33 Two-Row Cylindrical Roller Radial Bearings

Dynamic Load Rating C11 TIMKEN NNU4988MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Backing Housing Diameter Ds TIMKEN NNU4088MAW33 Two-Row Cylindrical Roller Radial Bearings

Backing Housing Diameter Ds TIMKEN NNU4088MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Chamfer r1smin3 TIMKEN NNU4172MAW33 Two-Row Cylindrical Roller Radial Bearings

Chamfer r1smin3 TIMKEN NNU4172MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Width B TIMKEN NNU4940MAW33 Two-Row Cylindrical Roller Radial Bearings

Width B TIMKEN NNU4940MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Lubrication Groove g TIMKEN NNU49/560MAW33 Two-Row Cylindrical Roller Radial Bearings

Lubrication Groove g TIMKEN NNU49/560MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Lubrication Hole Diameter h TIMKEN NNU4068MAW33 Two-Row Cylindrical Roller Radial Bearings

Lubrication Hole Diameter h TIMKEN NNU4068MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Width B TIMKEN NNU49/500MAW33 Two-Row Cylindrical Roller Radial Bearings

Width B TIMKEN NNU49/500MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Thermal Speed Ratings - Grease TIMKEN NNU4960MAW33 Two-Row Cylindrical Roller Radial Bearings

Thermal Speed Ratings - Grease TIMKEN NNU4960MAW33 Two-Row Cylindrical Roller Radial Bearings

-

Lubrication Groove g TIMKEN NNU4144MAW33 Two-Row Cylindrical Roller Radial Bearings

Lubrication Groove g TIMKEN NNU4144MAW33 Two-Row Cylindrical Roller Radial Bearings

Thrust cylindrical roller bearings FAQS

QWhat's the features of tapered roller thrust bearings?

ASeparable design The shaft and housing washers and the roller and cage thrust assemblies of tapered roller thrust bearings with cages can be mounted separately. Low friction The optimized roller end design and surface finish on the flange promote lubricant film formation, resulting in lower friction. This also reduces frictional heat and flange wear. Long service life Depending on the design, crowned or logarithmic raceway profiles optimize the load distribution along the contact surfaces, reduce stress peaks at the roller ends, and reduce the sensitivity to misalignment compared with conventional straight raceway profiles Enhanced operational reliability The surface finish on the contact surfaces on the rollers and raceways supports the formation of a hydrodynamic lubricant film. High load carrying capacity The rollers incorporated in SKF tapered roller thrust bearings are manufactured to such close dimensional and geometrical tolerances that they are practically identical. This provides optimal load distribution and enables the bearings to accommodate heavy axial loads.

QWhat's the designs and variants of tapered roller thrust bearings?

Asingle direction tapered roller thrust bearings double direction tapered roller thrust bearings screw-down bearings

QWhat's the temperature limits of tapered roller thrust bearings can be limited by?

AThe permissible operating temperature for tapered roller thrust bearings the dimensional stability of the bearing washers, spacer sleeves and rollers the cage the seal the retaining component the lubricant

QWhat's the application of tapered roller thrust bearings?

AIt is only applicable to the parts with one side axial load and low speed, and only to the parts with one side axial load and low speed, such as crane hook, instant water pump, instant centrifuge, Jack, such as crane hook, instant water pump, instant centrifuge, Jack, low speed reducer, etc. The bearing's shaft ring, seat ring and rolling body are separated, and the speed reducer, etc. The shaft ring, seat ring and rolling element of the bearing are separated and can be installed and disassembled separately.

Hot Searches

- • Chamfer rsmin TIMKEN A-5224-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • O.D. D TIMKEN A-5236-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Geometry Factor Cg3 TIMKEN A-5234-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Thermal Speed Ratings - Oil TIMKEN A-5226-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Thermal Speed Ratings - Grease TIMKEN A-5238-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • DUR/DOR F/E TIMKEN A-5244-WM A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Thermal Speed Ratings - Grease TIMKEN A-5232-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Dynamic Load Rating C11 TIMKEN A-5248-WM A5200 Metric Cylindrical Roller Radial Bearing PDF

- • DUR/DOR F/E TIMKEN A-5228-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Width B TIMKEN A-5230-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Weight TIMKEN A-5220-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Width B TIMKEN A-5222-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- Thrust cylindrical roller bearings

- Limiting Speed TIMKEN 220TP175 Thrust cylindrical roller bearings

- Min operating temperature, Tmin NTN WS81228 Thrust cylindrical roller bearings

- Nlim (oil) NTN 81215T2 Thrust cylindrical roller bearings

- A5200 Metric Cylindrical Roller Radial Bearing

- Weight TIMKEN A-5240-WM A5200 Metric Cylindrical Roller Radial Bearing

- Chamfer rsmin TIMKEN A-5224-WS A5200 Metric Cylindrical Roller Radial Bearing

- Thermal Speed Ratings - Oil TIMKEN A-5226-WS A5200 Metric Cylindrical Roller Radial Bearing

- Single row Cylindrical roller bearing

- 60 mm x 130 mm x 46 mm da max NTN NJ2312ET2C4 Single row Cylindrical roller bearing

- 80 mm x 140 mm x 26 mm Characteristic cage frequency, FTF SNR NU.216.EG15J30 Single row Cylindrical roller bearing

- 70 mm x 125 mm x 24 mm Cage Material NTN NU214C3 Single row Cylindrical roller bearing

- About Us

- Company Profile

- Contact Info

- Site Map

- Sitemaps